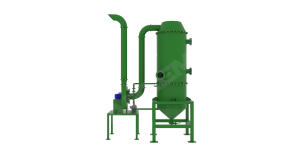

SCRUBBER

Scrubber https://www.apzem.in

A scrubber or scrubber system is a system, that is used to removed harmful materials from industrial exhaust gases before they are released into the environment.

Spray Scrubber

Spray scrubber can be used to capture a particulate matter of size 2 microns and large particulates. It can be also remove gaseous pollutants. Apzem is a leading manufacturer of spray tower scrubber in India. Apzem’s wet spray scrubbers is incorporating standard design features and so it is extremely compact and can be easily customized based on the requirements.

Applications:

- Chemical industries

- Pulp & paper industries

- Petrochemical industries

- Steel making

- Corn Processing Facilities

- Food Manufacturing

- Pharmaceutical industries

A Devices called as a wet scrubbers trap suspended particles by direct contact with as spray of water or other liquid. In that effect, a scrubber washes the particulates out of the dirty airstream as they collide with and are entrained by the countless tiny droplets in the spray.

Working of Spray Scrubber

A scrubber is a cleaning installation whose main purpose is to neutralize harmful components in industrial air or waste gas streams. The removal of gas particles causing many problems from the gaseous stream during the process is necessary before disposing of the gases in an open air.

In some cases, the use of a gas scrubber may allow recovering a certain raw material after the treatment. A big advantage is the versatility of the gas scrubber in different areas. It includes the chemical industry, the pharmaceutical industry, and the surface treatment.

The installation functions by bringing the gas stream in contact with as washing liquid. Due to this contact, certain gaseous components are dissolved and remain in the water.

There is an transfer of the components from the gas phase to the liquid phase. This is a absorption process. The solubility of the elements in the liquid will determined to what extent the gaseous components dissolve into the liquid phase.

Thus it is a great importance to work with the correct fluid being as the absorption agent. Also besides the water, several organic or inorganic washing liquids can be also used for this purpose

In these causes, certain chemicals or micro-organisms are added to the washing liquid in order to convert or neutralize the dissolved gases.

When we use as scrubber in an optimal manner, we can achieve a very high removal efficiency of the harmful gas particles. Therefore, the fumes are released in the outside air are no longer damaging to the environment.

Purpose of Scrubbers

Scrubber systems are used as air pollution control devices that removed harmful particles, gases, or chemical byproducts from industrial exhaust streams. While not found on a many older industrial chimneys, new government regulations are requiring them to be added or constructed as an emissions control device.

Advantage

Scrubber can be classified by their use and the method they use to remove particulates. The main advantages of scrubbers is the continual use of the cheaper bunker fuel than low Sulphur fuel and thereby reducing the switching cost to an entirely new fuel system

A scriber is a hand tool used in metal work to mark lines on work pieces, prior to machining. The process of using a scriber is called as scribing, and is just part of the process of marking out.

Scrubber can be classified by their uses and the method they used to remove particulates. The main advantages of scrubbers is the continual use of the cheaper bunker fuel than low Sulphur fuel and thereby reducing the switching cost to an entirely new fuel system

Scrubber is a cleaning installation whose main purpose is to neutralize the harmful components in industrial air or waste gas stream. The removal of gas particles causing a many problems from the gas stream during the process is necessary before disposing of the gases in the open air.