Product Details

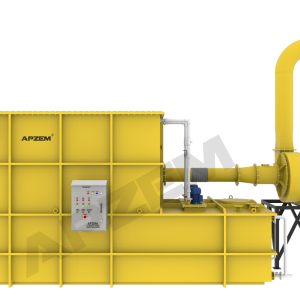

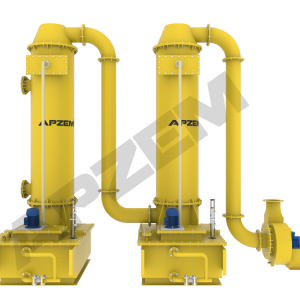

Wet VOC Scrubber

wet voc scrubber

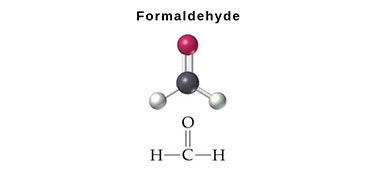

Volatile Organic Compounds (VOCs) are the toxic chemicals which are very harmful to humans and the environment. There is need of feasible method to remove these VOCs. Various methods including physical, chemical and biological treatments are available to remove VOCs either by destruction or recovery. Water scrubbing of VOC’s are highly efficient depending on its solubility and vapour pressure. The absorption of VOCs in water are most practical for water scrubber. Wet scrubber will be suitable for treating exhaust gases with high concentration VOCs.

Product CatalogueDescription

Wet VOC Scrubber

wet voc scrubber

Volatile Organic Compounds (VOCs) are the toxic chemicals which are very harmful to humans and the environment. There is need of feasible method to remove these VOCs. Various methods including physical, chemical and biological treatments are available to remove VOCs either by destruction or recovery. Water scrubbing of VOC’s are highly efficient depending on its solubility and vapour pressure. The absorption of VOCs in water are most practical for water scrubber. Wet scrubber will be suitable for treating exhaust gases with high concentration VOCs.

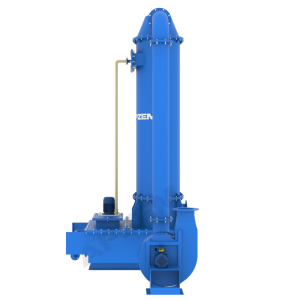

Working principle

VOC wet scrubber works on principle of absorption technology. A column in which gas is passed at bottom and liquid is sprayed at opposite direction. Packing material is filled to bring the intimate contact between gas and liquid. There are two things happening here, providing cooling for exhaust gas and removing solvent vapour from exhaust.

Apzem provides complete packages from start to end including water level controller using automated solenoid valve, pH controller with dosing system.

- Liquid to Gas (L/G) ratio: Liquid required to cover / wet gas passed through the column. It is determined based on pollutants solubility in (Henry’s law) and solvent.

- Flooding: If the liquid is not sprayed equally in the column, the will pass in one side of the column, this leads to inefficiency of scrubbing. Normally, 60 – 80 % of flooding will be considered as optimum design.

- Selection of packing material: Generally packing material helps to increase the surface area for mass transfer between gas and liquid. This surface area / mass transfer area varies based on the size, shape and material of construction. Smaller the size, higher the efficiency and higher the pressure drop, and vice versa. Improper selection of packing leads to the higher power consumption and fouling in operation, scale formation etc.

- Solvent selection: Normally, water is used to scrub the solvent fumes. This forms the diluted solvent solution, and it can be reused. However, it cannot be reused if there is a mixture of VOCs.

| AIR HANDLING VOLUME |

|

| TYPE |

|

| SYSTEM PRESSURE DROP |

|

| REMOVAL EFFICIENCY |

|

| MOC |

|

| PACKING MATERIAL |

|

| HEIGHT OF TRANSFER UNIT (EFFECTIVENESS OF PACKING) |

|

| FLOODING |

|

| NOZZLES |

|

| STRUCTURE |

|

| CONTROL SYSTEM |

|

| ACCESSORIES |

|

| SAFETY ACCESSORIES

|

|

| Scrubbing liquid |

|

| Blower |

|

| Control panel |

|