Product Details

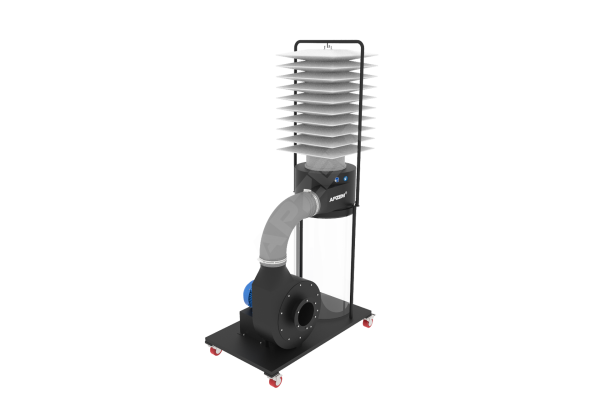

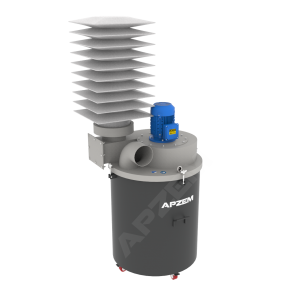

Single Stage Dust Collector

Single stage dust collectors are the most simplest and efficient industrial dust collectors and is predominately finds its usage in woodworking industries and its also called as wood dust collectors. As per NFPA (National Fire Protection Association) Codes and Standards, Wood chips / dusts are combustible in nature and should be collected and handled safely in wood shops, woodworking industries in order to avoid Fire and explosion risks.

Product CatalogueDescription

Single stage dust collector

WOOD DUST COLLECTOR ( SINGLE STAGE )

Wood dust collector is designed to capture dust and wood chips from wood working machines, such as table saws, jointers, and planers. The air drawn in by the dust collector is filtered before it returns to the workspace. Radial Arm Saw, Table and Circular Saws, Swing Saw, Band Saw, Disc Sander, Drum Sander , Jointer, Belt Sander, Lathe, Planer, CNC Router etc. are some of the common wood working machines producing flying wood dusts, chips etc and needs a proper dust control equipment or dust collection equipment or system in place to extract all dusts, filter it & collect it to safely dispose it.

- Fully mobile with built-in casters

- Dust bags are 99% efficient.

- High filtration area.

- Easy filter replacement.

- Quiet operation.

- 14 gauge, powder-coated, steel casing

- Easy handling of dust collection bag

- Industrial-quality construction effectively handles collection of wood chips and sawdust

- Quick-install collection bag makes emptying and re-attaching a snap

- Single-stage design for economical and quiet operation

- Includes four casters for maneuverability and total portability

- High air velocity (CFM) design stands up to any competitive specifications

- Permanently lubricated, totally enclosed, fan-cooled motors are rated for continuous-duty

|

BASIC DETAILS |

SD310 |

SD320 |

| SUCTION CAPACITY (CMH/CFM) | 680/400 | 1360/800 |

| OVERALL DIMENSIONS (L X W X H) | 900 X 520 X 1680 mm | 1050 X 580 X 1900 mm |

| MACHINE WEIGHT (APPROX.) | 75kg | 90Kg |

| WOOD PACKING SIZE (L X W X H) | 1100 X 720 X 1880 mm | 1250 X 780 X 2100 mm |

| SHIPPING WEIGHT (APPROX.) | 175kg | 200Kg |

| MOTOR POWER | 1HP | 2HP |

| MOTOR SPEED | 2880 RPM | 2880 RPM |

| POWER SUPPLY | 3 PHASE / 50Hz | 3 PHASE / 50Hz |

| RATED CURRENT | 1.6 A | 3.2 A |

| NOISE LEVEL | <82 dB | <82 dB |

| STATIC PRESSURE | 100mm OF WG | 100mm OF WG |

| INLET SIZE | 100mm | Y piece (100mm dia * 2 ) |

FILTER DETAILS

| FILTER SURFACE | 16.6 Sq. Ft | 25 Sq. Ft |

| Type of Filter | Filter Bag | Filter Bag |

| Filter Material | Non Woven Needle Felt Polyester | Non Woven Needle Felt Polyester |

| Filter Efficiency | 99% Efficiency @ 5Microns | 99% Efficiency @ 5Microns |

| Cartridge Filter | Optional | Optional |