Product Details

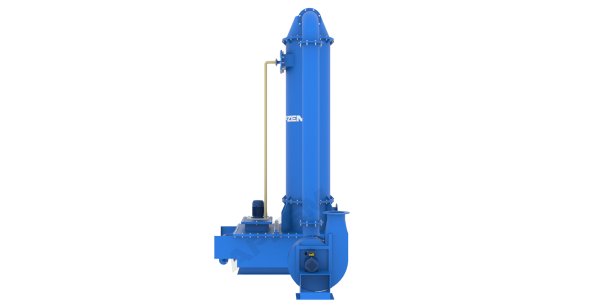

Phosphating Scrubber

Phosphating is the widely used pretreatment process for metal surfaces and polishing of ferrous and non ferrous materials. It plays an important role in automobile and appliances industries because of its corrosion resistance, wear resistance and speed of operation. Phosphate coating is typically used to coat any steel parts to prevent from corrosion and can be used for pre treatment of any material or equipment before doing painting or coating. Chemicals used for phosphate coatings are Manganese, Iron and Zinc.

Product CatalogueDescription

Phosphating Scrubber

PHOSPHATING SCRUBBER

Phosphating is the widely used pretreatment process for metal surfaces and polishing of ferrous and non ferrous materials. It plays an important role in automobile and appliances industries because of its corrosion resistance, wear resistance and speed of operation. Phosphate coating is typically used to coat any steel parts to prevent from corrosion and can be used for pre treatment of any material or equipment before doing painting or coating. Chemicals used for phosphate coatings are Manganese, Iron and Zinc. A part of material is dipped into a tank containing phosphoric acid solution causes a chemical reaction which makes the salts to bond on the part. Common parts used in phosphating are automotive parts such as clutches, engine components. Increasing regulations for controlling fumes from phoshpating tanks and environmental concerns leads to requirement of wet scrubber.

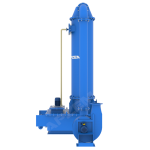

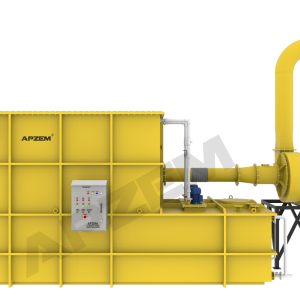

Apzem design and manufacture wet scrubber which is suitable for controlling phosphating fumes, acids and alkali. We design hood and ducting for source capturing using ACGIH standard, without allowing to spread in the working area. The captured fumes are treated by passing through a wet scrubber. A cylindrical device in which gas is passed from the bottom and scrubbing liquid is sprayed on the top to neutralize the gas pollutants. Wet scrubber removes pollutants by absorbing in liquid and neutralizing by chemical agents present in the liquid.

Typical processes applied for Phosphating are

- Activation

- Acid/Alkali degreasing

- Lubrication

- Acid Pickling

- Rinsing

| AIR HANDLING VOLUME |

|

| TYPE |

|

| SYSTEM PRESSURE DROP |

|

| REMOVAL EFFICIENCY |

|

| MOC |

|

| PACKING MATERIAL |

|

| HEIGHT OF TRANSFER UNIT (EFFECTIVENESS OF PACKING) |

|

| FLOODING |

|

| NOZZLES |

|

| STRUCTURE |

|

| CONTROL SYSTEM |

|

| ACCESSORIES |

|

| SAFETY ACCESSORIES

|

|

| Scrubbing liquid |

|

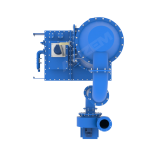

| Blower |

|

| Control panel |

|