Product Details

Ion implant scrubber

A dry scrubber use catalyst to remove toxic components by chemical adsorption on the surface. The adsorption does not depend on pollutant concentration and contact time, adsorption will take place in very short period of time. When the pollutants adsorbed on to the surface, the catalyst will convert the simple chemicals which is non-toxic and can be disposed of easily. The catalyst is to be replaced frequently when it saturated with pollutants. Optional sensor will be provided for indication of catalyst saturation.

Product CatalogueDescription

Ion implant scrubber

ion implant scrubber

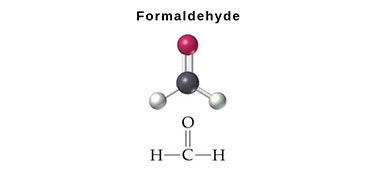

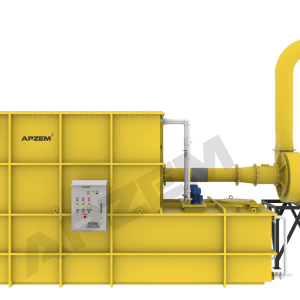

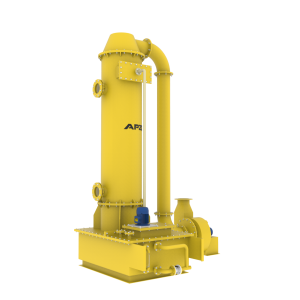

A dry scrubber use catalyst to remove toxic components by chemical adsorption on the surface. The adsorption does not depend on pollutant concentration and contact time, adsorption will take place in very short period of time. When the pollutants adsorbed on to the surface, the catalyst will convert the simple chemicals which is non-toxic and can be disposed of easily. The catalyst is to be replaced frequently when it saturated with pollutants. Optional sensor will be provided for indication of catalyst saturation. This scrubber is recommended for gas stream with low concentration of toxic pollutants, because of adsorption capacity of catalyst. In case of emergency applications, it will be good to provide scrubber for gas stream with high concentration. However, the gas stream with high concentrations will not be scrubbed continuously. The acids used are extremely corrosive and the fume generated from the process attack all tissues of the body.

Apzem approach is to eliminate acid fumes from your process using adsorption technology. Specialized adsorption media will be used to get higher removal capacity rather than normal media. The saturated media can be disposed easily in non-hazardous landfills. The scrubber is available as portable and centralized scrubber system based on conditions and requirements.

Featuresn of ion implant scrubber

- Performance Guaranteed

- Low maintenance

- Low pressure drop, Minimal energy cost

- No water, ETP is not required

- No hazardous by-product

- Chemical Reactor vents

- Laboratory

- Hospital

- Food processing area

- Storage tank vent

- Air flow rate from 50 CFM to 2000 CFM

- Concentration: 1 ppm to 200 ppm (continuous) up to 2000 ppm (Intermittent)

- Removal efficiency: up to 99.99 %

- Material of Construction: MS with Epoxy lining

- Construction: Heavy Gauge, Fully welded cabinet, robust construction

Dimensions

| Model | Air flow rate (CFM) | Dimension

Diameter (mm) |

Height (mm) |

| ADS-30 | 100 | 300 | 1400 |

| ADS-45 | 300 | 450 | 1500 |

| ADS-60 | 500 | 600 | 1500 |

| ADS-75 | 800 | 750 | 1650 |

| ADS-90 | 1000 | 900 | 1700 |

| ADS-105 | 1500 | 1050 | 2000 |

| ADS-120 | 2000 | 1200 | 2200 |

https://www.apzem.in/index.php/product/ion-implant-scrubber/

Blower: Direct drive, High efficiency, Low noise