Product Details

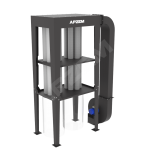

Bag Filter Dust collectors

Bag Filter Dust collectors are industrial dust collectors and is predominately finds its usage in woodworking industries and its also called as wood dust collectors. As per NFPA (National Fire Protection Association) Codes and Standards, Wood chips / dusts are combustible in nature and should be collected and handled safely in wood shops, woodworking industries in order to avoid Fire and explosion risks. Also Prolonged Exposure to wood chips, saw dusts etc in a wood industries creates a serious health problems to workers. See below for eight hour average exposure limits to wood dusts as stated by ACGIH (American Conference of Industrial Hygienists), NIOSH (National Institute for Occupational Safety and Health) and OSHA (Occupational Safety and Health Administration) Standards.

Product Catalogue

Description

Bag Filter Dust collectors

BAG FILTER DUST COLLECTOR

Bag Filter Dust collectors are industrial dust collectors and is predominately finds its usage in woodworking industries and its also called as wood dust collectors. As per NFPA (National Fire Protection Association) Codes and Standards, Wood chips / dusts are combustible in nature and should be collected and handled safely in wood shops, woodworking industries in order to avoid Fire and explosion risks. Also Prolonged Exposure to wood chips, saw dusts etc in a wood industries creates a serious health problems to workers. See below for eight hour average exposure limits to wood dusts as stated by ACGIH (American Conference of Industrial Hygienists), NIOSH (National Institute for Occupational Safety and Health) and OSHA (Occupational Safety and Health Administration) Standards.

- Mechanical separation.

- Automatic Reverse air Pulse jet cleaning. Solenoid Valves

- Bulk materials handling,

- conveying, screening, sieving, mixing, bin -silo venting

- Building materials manufacturing,

- Chemical, plastics and pharmaceutical powders

- Processes with light or medium dust loading etc.

|

Model No. |

APZEM Pulse Jet Bag filter |

|

Air Handling Volume |

2000 CFM (3400 m3/hr) |

|

Design Standard |

Industrial Hygiene standard. |

|

Overall Size |

1500 (L) X 1800v(D) X 2100(H) mm |

|

Vacuum (Max) |

300 mm of W.C (12 IWG) |

|

Power Requirements |

7.5HP, Three Phase, 415V, 50Hz Motor: Siemens/ABB/CGL/Marathon Direct Drive motor assembly. |

|

Electrical Wire |

5 wire, Three Phase, 3 meter Length. |

|

Sound Rating |

72 dBA |

|

Operating Temperature |

05 – 50 Deg C |

|

Filtration |

Bag filter of high particulate capturing efficiency. |

|

Dust collection |

Large dust collection bin. |

|

MOC |

Cabinet fully made of Carbon Steel. |

|

Exterior Finish |

Blue / White Epoxy Paint |

|

Filter Cleaning |

Automatic with reverse air pulse cleaning. |

- Differential Pressure switch / Magnahelic Gauge. Spark Arresters to isolate sparks entering filter compartment.

- FRL unit.

- Lifting Lugs

- Dust collector control panel with DOL starter. Rotary air lock valve (optional)