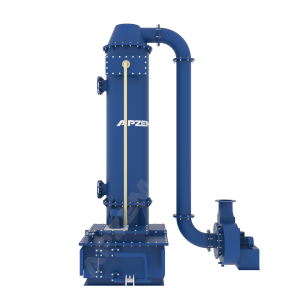

Dry Scrubber

Products

Ion implant scrubber

Ion implant scrubberA dry scrubber use catalyst to remove toxic components by chemical adsorption on the surface. The adsorption does not depend on pollutant concentration and contact time, adsorption will take place in very short period of time. When the pollutants adsorbed on to the surface, the catalyst will convert the simple chemicals which is non-toxic and can be disposed of easily. The catalyst is to be replaced frequently when it saturated with pollutants. Optional sensor will be provided for indication of catalyst saturation.

[su_button url="https://www.apzem.in/contact/" target="blank" background="#8dc63f" size="7" radius="0" icon="icon: file-pdf-o"]Product Catalogue[/su_button]CVD Scrubber

CVD Scrubbercvd scrubber

Deposition by chemical reaction between reactants. It is a chemical process that deposits thin film of diverse chemical substances. A substrate is exposed to volatile precursors and react to generate required deposit. Simultaneously, the byproducts also generated from the process. Precursors used to deposit silicon is silane (SiH4).

[su_button url="https://www.apzem.in/contact/" target="blank" background="#8dc63f" size="7" radius="0" icon="icon: file-pdf-o"]Product Catalogue[/su_button]Dry VOC Scrubber

Dry VOC Scrubbervoc dry scrubber

Improving the process reliability is important for manufacturing large volume of goods. Industries have adopted various chemicals methods to ensure the process go smoothly. Dry gas scrubbing process remain important stage in ensuring the environmental regulations. Dry scrubbing of VOCs from exhaust gas is becoming a feasible alternative technology to the wet scrubbing process. Unlike wet scrubber, dry scrubber does not saturate with moisture. It is an important part of gas filtration and plays significant role in not only maintaining environmental standards but also in maintaining some processes.

[su_button url="#" target="blank" background="#8dc63f" size="7" radius="0" icon="icon: file-pdf-o"]Product Catalogue[/su_button]Metal Etch Scrubber

Metal Etch ScrubberMeta Etch Scrubber

Traditionally etching was performed by hand. It was implemented by using sharp tipped tool to etch metal according to desired design pattern. This process is time consumable. Nowadays the most popular metal etching is acid etching as the chemical technology has improved, since chemical milling is much faster than mechanical milling. Metal etching is process of creating design on metal surface using acid or mordant. The most commonly used chemicals are nitric acid, hydrochloric acid, potassium chlorate and Ferric Chloride. These acids will be used in different concentrations.

[su_button url="https://www.apzem.in/contact/" target="blank" background="#8dc63f" size="7" radius="0" icon="icon: file-pdf-o"]Product Catalogue[/su_button]MOCVD Scrubber

MOCVD ScrubberMOCVD (Metal Organic Chemical Vapor Deposition) is a technology used in semiconductor industry, including LEDS, Lasers, Solar cells and field effect transistors. This technology is used to deposit very thin layers of atoms onto a semiconductor wafer. It is the most important manufacturing MOCVD process for III – V semiconductors, especially based on Gallium Nitride (GaN).

[su_button url="https://www.apzem.in/contact/" target="blank" background="#8dc63f" size="7" radius="0" icon="icon: file-pdf-o"]Product Catalogue[/su_button]Semiconductor Scrubber

Semiconductor ScrubberThe fast growth in electronic industry has brought new environmental challenges for processes applied in manufacturing of semiconductor chips, which are important key part of many advanced electronic devices.Potentially hazardous chemicals; arsine, silane and phosphine are mainly used in fabrication of semiconductor by chemical vapor deposition (CVD).

[su_button url="https://www.apzem.in/contact/" target="blank" background="#8dc63f" size="7" radius="0" icon="icon: file-pdf-o"]Product Catalogue[/su_button]