Product Details

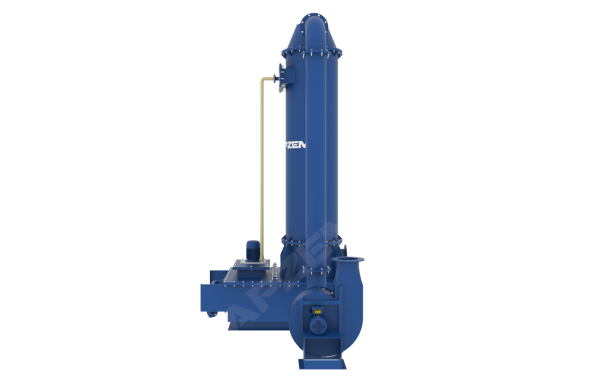

H2SO4(Sulfuric Acid) Scrubber

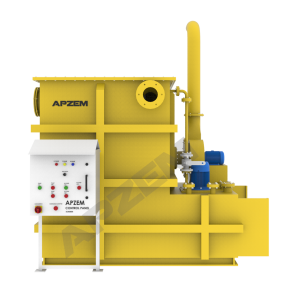

sulfuric acid scrubber

Many chemical industries generates and exhausts sulphur based substances such as sulphuric acids or sulphur dioxide from various processes. Sulfuric acid fumes are very corrosive and it is strongly irritant to the respiratory if is directly inhaled. Apzem have experienced in controlling and neutralizing the sulphuric acid fume using a packed bed column with caustic recirculation.

Description

Sulfuric Acid Scrubbers

sulfuric acid scrubber

Many chemical industries generates and exhausts sulphur based substances such as sulphuric acids or sulphur dioxide from various processes. Sulfuric acid fumes are very corrosive and it is strongly irritant to the respiratory if is directly inhaled. Apzem have experienced in controlling and neutralizing the sulphuric acid fume using a packed bed column with caustic recirculation.

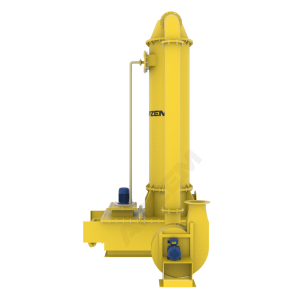

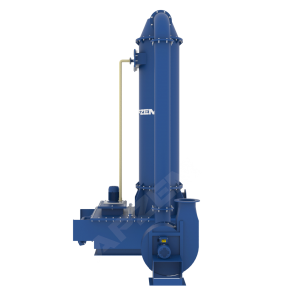

The scrubber system consists of packed bed column with bottom tank, recirculation pump, mist eliminator and blower. We design and fabricate custom wet scrubber unit which can be fit in the site location and will assure you performance and minimum requirements of maintenance.

Working principle

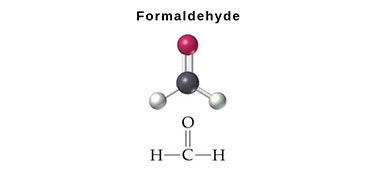

H2SO4 Scrubber works on principle of absorption technology. A column in which gas is passed at bottom and liquid is sprayed at opposite direction. Packing material is filled to bring the intimate contact between gas and liquid. There are two things happening here, providing cooling for exhaust gas and removing H2SO4 gas from exhaust.Apzem provides complete packages from start to end including water level controller using automated solenoid valve, pH controller with dosing system.

- Liquid to Gas (L/G) ratio: Liquid required to cover / wet gas passed through the column. It is determined based on pollutants solubility in (Henry’s law) and solvent.

- Flooding: If the liquid is not sprayed equally in the column, the will pass in one side of the column, this leads to inefficiency of scrubbing. Normally, 60 – 80 % of flooding will be considered as optimum design.

- Selection of packing material: Generally packing material helps to increase the surface area for mass transfer between gas and liquid. This surface area / mass transfer area varies based on the size, shape and material of construction. Smaller the size, higher the efficiency and higher the pressure drop, and vice versa. Improper selection of packing leads to the higher power consumption and fouling in operation, scale formation etc.

- Solvent selection: Normally, water is used to scrub the hcl fumes if the concentration is high, greater than 3000 ppm. This forms the diluted H2SO4 solution, and it can be reused. However, it does not work for lower concentration. NaOH will be used as solvent to increase the absorption efficiency and to scrub continuously.

| AIR HANDLING VOLUME |

|

| TYPE |

|

| SYSTEM PRESSURE DROP |

|

| REMOVAL EFFICIENCY |

|

| MOC |

|

| PACKING MATERIAL |

|

| HEIGHT OF TRANSFER UNIT (EFFECTIVENESS OF PACKING) |

|

| FLOODING |

|

| NOZZLES |

|

| STRUCTURE |

|

| CONTROL SYSTEM |

|

| ACCESSORIES |

|

| SAFETY ACCESSORIES

|

|

| Scrubbing liquid |

|

| Blower |

|

| Control panel |

|

https://www.apzem.in/index.php/product/sulfuric-acid-scrubber/