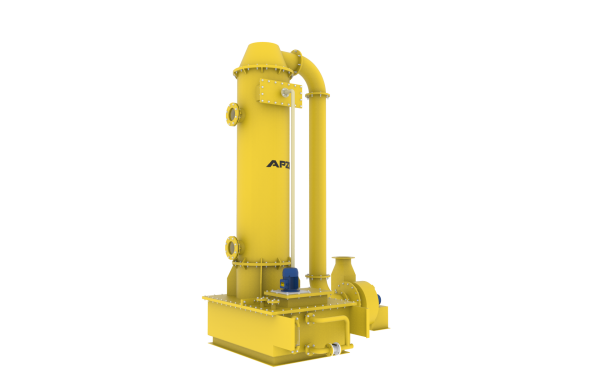

Product Details

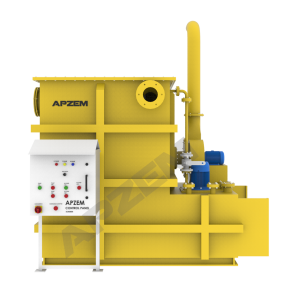

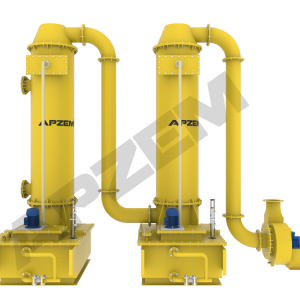

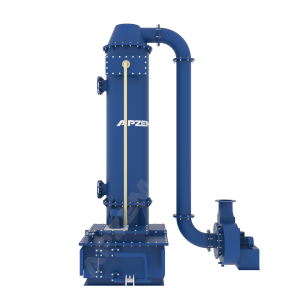

NaOH Scrubber

Caustic scrubbing technology is used for removal of acidic pollutants in exhaust gas from different industries.A cylindrical column consist of packing materials and spray nozzles in which the contaminated gas is passed. Pollutants from the gas dissolve in the liquid based on the absorption technology. Spray nozzles are arranged in such a way that spray zones should cover cross sectional area of column. There is packing material in the tower to enhance contact between liquid and gas.

Product CatalogueDescription

NaOH Scrubber

NaOH Scrubber

Caustic scrubbing technology is used for removal of acidic pollutants in exhaust gas from different industries.

A cylindrical column consist of packing materials and spray nozzles in which the contaminated gas is passed. Pollutants from the gas dissolve in the liquid based on the absorption technology. Spray nozzles are arranged in such a way that spray zones should cover cross sectional area of column. There is packing material in the tower to enhance contact between liquid and gas.

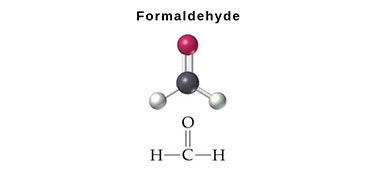

Caustic scrubber is mainly used for H2S scrubbing

Scrubbing of H2S using NaOH has been applied various industries. However, we can apply this technology for only if H2S concentration is low level. For this case, we can just remove the H2S from the exhaust gas, we cannot get back the by product.

If the H2S concentration is very high, the consumption of caustic will be more. Then it will be uneconomical to remove the H2S. To make it economical, we have look for reselling of by product formed from the reaction.

In the scrubbing process, the following reaction takes place

H2S + NaOH ————–> NaHS + H2O ————— reaction 1

NaHS + NaOH ———–> Na2S + H2O —————– reaction 2

NaOH reacts with H2S to give NaHS (Sodium hydrosulfide) as per reaction 1. If the quantity of NaOH is more reaction 2 is favourable, then it leads to formation of Na2S (Sodium Sulfide). Generally, NaHS is more valuable by product than Na2S. In order to reduce the caustic consumption by 50 % and as well as to increase the by-product sale value, it is required to not to favour the reaction 2. We design and develop the caustic scrubber to achieve reduction in caustic consumption and increase the by-product sale value.

pH/Conductivity in scrubbing liquid

The pH in the scrubbing liquid is continuously monitored and adjusted to maintain the constant removal efficiency. If the pH level in the Scrubbing tank decreases the efficiency of scrubber will be decreased drastically. Maintaining the pH manually will be a problem for continuous production conditions. In order to avoid that, the Dosing System along with pH monitor will be fitted. The pH monitor will continuously monitor the pH level. If the pH falls below or raises it will automatically raises the audio visual alarm. And also operates the dosing pump through the relay output accordingly thus maintaining the pH level.

Note: pH is considered if the concentration of scrubbing liquid is less than 4 %. If the scrubber uses strong caustic (10 – 15 %), the pH is not recommended because direct exposure of pH probe/electrode to high concentrated caustic will damage the pH probe, thus leads to fluctuation/failure in pH monitoring.

Conductivity is non-specific for particular chemicals. Conductivity meter will respond for both reactant and product in scrubbing liquid. If the scrubbing chemical decrease, there will be decrease in the conductivity. The scrubbing liquid can be discharged and directed to ETP, if there is significance drops in conductivity.

Features of NaOH Scrubber

- Amount of H2S at inlet gas

- Temperature and pressure of exhaust gases

- Requirement of H2S concentration at outlet

- Other acid gases along with H2S

- By product value

- Acid gases Chemical industries

- Dust and particles from cremation

- Metal industries

- Rubber industries

- Foundries

- Waste incineration industries

- Pharmaceutical industries

- Power dust from Glass industries

- Fertilizer industries

- Plastic industries