Aerospace

AEROSPACE INDUSTRY – Odor, Fume & Dust Control Solution

The manufacture of electrodes, cells and modules/packs for large-format power batteries is still in its infancy. One thing, however, is already perfectly clear: the battery manufacturing operation needs to become faster and less expensive if lithium-ion energy storage technology is to establish itself successfully in the target markets. The sensitive chemistry of the cells means that these cost and time savings absolutely cannot come at the expense of quality, which needs to remain very high. The solution, therefore, lies in fully automating and integrating production lines.

The automation portfolio needs to provide comprehensive support for the development process, from the pilot system to in-line integration. Totally Integrated Automation from Siemens makes it possible to optimize all processes throughout the production line and across the entire lifecycle of the plant. Uniform data management, engineering and communication standards ensure that all production steps, from electrode manufacturing to cell assembly to pack mounting and final quality tests, are optimally coordinated.

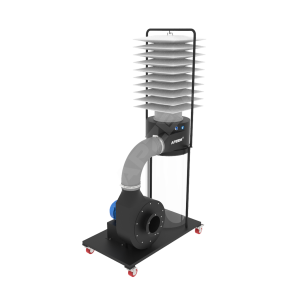

DUST REMOVAL SOLUTION - MOBILE DUST COLLECTOR FOR POWDER DUST

Portable Dust Collector

Apzem’s Portable Dust Collector suitable for capturing dust at the source. Portable dust collectors are self contained system with fully automatic pulse air cleaning arrangement and industrial grade castor wheel affixed at bottom for maximum portability. As an optional upgrade some of our portable dustcollectors are accompanied with flexible arm with hood and control arrangement Portable dustcollectors will be an economical option when sources generating dusts is not fixed at one location

AUTOMATIC PULSE AIR CLEANING ARRANGEMENT

- Fully mobile with built-in casters

- Cartridge filters are 99% efficient.

- 12 gauge, powder-coated, steel casing

- Easy handling of dust tray.

- Filter choking alarm

- Self cleaning reverse pulse system

- 3 meter Flexible arm with capturing Hood

SIFTING DUST REMOVAL SOLUTION - BAGFILTER DUST COLLECTOR

Sifting Dust Removal

Bagfilter or Baghouse dust collector are a giant centralized industrial dust control equipment used for collection and filtration of harmful, nuisance dusts in various industries like Food Industry , cement plants, Fertilizer Industries, Woodworking & Glass manufacturing industries and other Manufacturing Industries.

- Flow:upto30,000 CFM

- Filtration :upto5 microns

- MOC:Mild Steel / SS 304 /SS316

- Finish: Powder coated / Matt finish

- Power option :3 Phase

HIGHLY ADVANCED FEATURES

Related Products :

Soldering

SOLDERING FUMES – FUME EXTRACTION SOLUTION FOR SOLDERING FUMES

Soldering enables the joining of metal parts by melting a filler metal to attach wires and other metallic components. The fumes generated from melting solder especially solder containing Lead or Tin present are dangerous and require local ventilation to remove harmful smoke from the work area. Soldering application need to be properly ventilated to prevent toxic fumes from reaching the worker’s breathing zone.

There are a number of different industries such as the electronics assembly industry and electronics repair companies who must deal with the hazards of solder smoke. Fumes created by automated PCB soldering including wave soldering machines, handheld soldering irons, torch brazing and furnace brazing are often ignored because of the small volume of smoke generated. However, these applications still require careful consideration as dangerous fumes can impair employee’s respiratory tracts depending on the filler metals used.

Because manual soldering applications require working with tiny components, workers end up positioning their heads right above toxic rosin or lead solder fumes with a direct exposure into their throat, nasal passages and lungs, and as a result, they can experience respiratory complications. Rosin irritation can cause various side effects and the inhalation of lead fumes is carcinogenic. As lead oxide smoke collects in your lungs, it can be transferred into your bloodstream.

DUST REMOVAL SOLUTION - MOBILE DUST COLLECTOR FOR POWDER DUST

Portable Dust Collector

Apzem’s Portable Dust Collector suitable for capturing dust at the source. Portable dust collectors are self contained system with fully automatic pulse air cleaning arrangement and industrial grade castor wheel affixed at bottom for maximum portability. As an optional upgrade some of our portable dustcollectors are accompanied with flexible arm with hood and control arrangement Portable dustcollectors will be an economical option when sources generating dusts is not fixed at one location

AUTOMATIC PULSE AIR CLEANING ARRANGEMENT

- Fully mobile with built-in casters

- Cartridge filters are 99% efficient.

- 12 gauge, powder-coated, steel casing

- Easy handling of dust tray.

- Filter choking alarm

- Self cleaning reverse pulse system

- 3 meter Flexible arm with capturing Hood

SIFTING DUST REMOVAL SOLUTION - BAGFILTER DUST COLLECTOR

Sifting Dust Removal

Bagfilter or Baghouse dust collector are a giant centralized industrial dust control equipment used for collection and filtration of harmful, nuisance dusts in various industries like Food Industry , cement plants, Fertilizer Industries, Woodworking & Glass manufacturing industries and other Manufacturing Industries.

- Flow:upto30,000 CFM

- Filtration :upto5 microns

- MOC:Mild Steel / SS 304 /SS316

- Finish: Powder coated / Matt finish

- Power option :3 Phase

HIGHLY ADVANCED FEATURES

Related Products :

Welding

WELDING FUMES & DUST EXTACTION IN YOUR WORKPLACE

Poisonous gases, fumes and sparks are created anytime metals are welded together. It doesn’t matter what type of welding equipment is used or what type of metal is being welded. The fact that welding is among the most common industrial processes means that air filtration for welding and robotic welding is an important topic.

Welding takes place at industrial sites that use it as part of the manufacturing process, but it also takes place in workplaces that don’t use it for business purposes. The extraction of welding fumes is a critical part of any welding process, because the health risks are often severe.

HEALTH RISKS OF WELDING GASES & FUMES

The length of time you are exposed to welding gases and fumes, the type of welding, the effectiveness of your safety protection and your work environment all play a role in how serious the exposure risks will be. The fact that welding gases may not have an odor and can’t be seen by the naked eye makes them particularly dangerous.Heat from the welding flame may produce gases such as carbon monoxide, carbon dioxide and oxides of nitrogen. Gases and vapors may also be produced by coatings or solvents on the metal.

SCOURER DUST REMOVAL SOLUTION - MOBILE DUST COLLECTOR FOR POWDER DUST

Portable Dust Collector

Apzem’s Portable Dust Collector suitable for capturing dust at the source. Portable dust collectors are self contained system with fully automatic pulse air cleaning arrangement and industrial grade castor wheel affixed at bottom for maximum portability. As an optional upgrade some of our portable dustcollectors are accompanied with flexible arm with hood and control arrangement Portable dustcollectors will be an economical option when sources generating dusts is not fixed at one location

AUTOMATIC PULSE AIR CLEANING ARRANGEMENT

- Fully mobile with built-in casters

- Cartridge filters are 99% efficient.

- 12 gauge, powder-coated, steel casing

- Easy handling of dust tray.

- Filter choking alarm

- Self cleaning reverse pulse system

- 3 meter Flexible arm with capturing Hood

SIFTING DUST REMOVAL SOLUTION - BAGFILTER DUST COLLECTOR

Sifting Dust Removal

Bagfilter or Baghouse dust collector are a giant centralized industrial dust control equipment used for collection and filtration of harmful, nuisance dusts in various industries like Food Industry , cement plants, Fertilizer Industries, Woodworking & Glass manufacturing industries and other Manufacturing Industries.

- Flow:upto30,000 CFM

- Filtration :upto5 microns

- MOC:Mild Steel / SS 304 /SS316

- Finish: Powder coated / Matt finish

- Power option :3 Phase

HIGHLY ADVANCED FEATURES

Related Products :

NEERI tracking pollutants from Punjab and Haryana

NEERI tracking pollutants from Punjab and Haryana

National Environmental Engineering and Research Institute (NEERI) has started to track records on the pollutants levels from the two states; Punjab and Haryana. This project has been initiated because the stubble burning is at its peak in Punjab and Haryana after the Kharif season. This project has been initiated for the determination of the impact that has been made on Delhi’s Air Quality due to the stubble burning. This study is being done for Central Pollution Control Board (CPCB). Several teams are set up to monitor the air quality at places such as Nagpur, Delhi and Mumbai. Three monitoring station have been set up, one at Delhi and two at Punjab. The Air Quality is continuously being monitored since the station had been set up

In order to get the most accurate results the monitoring stations have set up at the interface of the rural and the urban areas. The air samples will be collected for finger print analysis after monitoring a week more. This is being keenly monitored because the particulates created by stubble burning is different from other normal pollutants. This project majorly focuses on the study of the pollutants and to correlate what type of particulates such as PM2.5, PM10, gaseous components, elemental and organic carbon etc. are being emitted. Most accurate results can be obtained only when the monitoring is done when the emission is at its peak. The concentration of PM2.5 is found to be 5 times higher than the permissible limits. The permissible limit for the PM2.5 is 60 microgram per cubic meter and for PM10 is 100.

Recently the level of PM2.5 and PM10 is found to present two to three times higher than the permissible level all over Punjab. National Green Tribunal has banned the unabated burning of agricultural residue in Punjab and Haryana. Yet a large quantities of stubble are being set to fire by farmers. A study states that around 15 million tons of residue is burned in 15 days to make room for new crop.

Burning large quantities of crops results in the emission of fine particulates which results in the increased pollutant level in the air. In winter, the atmospheric capacity of pollutant dispersion is very low. For better analyzing, Satellite Imagery is also used by NEERI. For this support is being provided by The Indian Institute Of Technology (Bombay). This satellite Imagery will capture the maximum heating points along with the direction of fumes.

Hyderabad has the worst air quality

Says the Pollution Control Board ( PCB )

Among the polluted cities of South India, Hyderabad is proved to have the worst air quality and it shows a peak increase in the level of Particulate Matter (PM2.5). Hyderabad has the highest number of red days as per the report posted in September, by the Central Pollution Control Board. The red days are those with greater levels of PM2.5 in air, which is harmful for all ages. PM2.5 Particles are less than 2.5 micrometer in diameters. It is said to be the most dangerous air-borne pollutants since they can easily enter the lungs. Pollution Control Board Officials states that though the PM2.5 level is high, the annual average level is maintained.

The reason for the sudden peak in the PM levels is due to the monsoon changes and there is no dispersion of particulate matter. In Hyderabad, Coastal area such as Vizag , has the higher level of pollution. Minimizing the level of PM2.5 can be done by controlling the number of vehicles and the also by ensuring that the heavy vehicles does not enter the highly polluted areas. The states Pollution Control Board has been working to keep the levels under the specified standards. Restoring of lost air quality within a short period of time is almost impossible.

Ongoing Construction sites and the increased use of concrete have paved way for the deterioration of the air quality. Open space with lots of plants acts as buffer zones and thereby helps us in reducing the pollution by controlling the spreading pollutants.

Moreover the ongoing Industrial Development in the nook and corner of the city will only lead to increase in the level of particulate matter. This level can be controlled only by applying proper pollution control standards. Industries must comply all the pollution standards specified by the Pollution Control Board. Yet the everlasting solution to this problem can be achieved only by creating awareness among the public.

Controlling the Pollution Levels

One way of reducing pollution is by continuous monitoring of the levels of pollution. Several Air Quality Monitors are available for monitoring the different Pollutants such as PM2.5 Monitor, PM10 Monitor, CO2 Monitor, NO2 Monitor, H2S Monitor, Industrial Air Quality Monitor, etc.

The best solution for reducing the pollution is by capturing the pollutants at the source. In industries several pollutants are released from various manufacturing process. Suitable Air Pollution control devices must be used to capture the pollutants. For each industries and their manufacturing process, various types of pollution control equipment such as Fume Extractors, Dust Collectors, Odor Control Scrubbers, Wet Scrubbers , Dry Scrubbers, Soldering Fume Extractors, Welding Fume Extractors , Downdraft Table etc. are available.