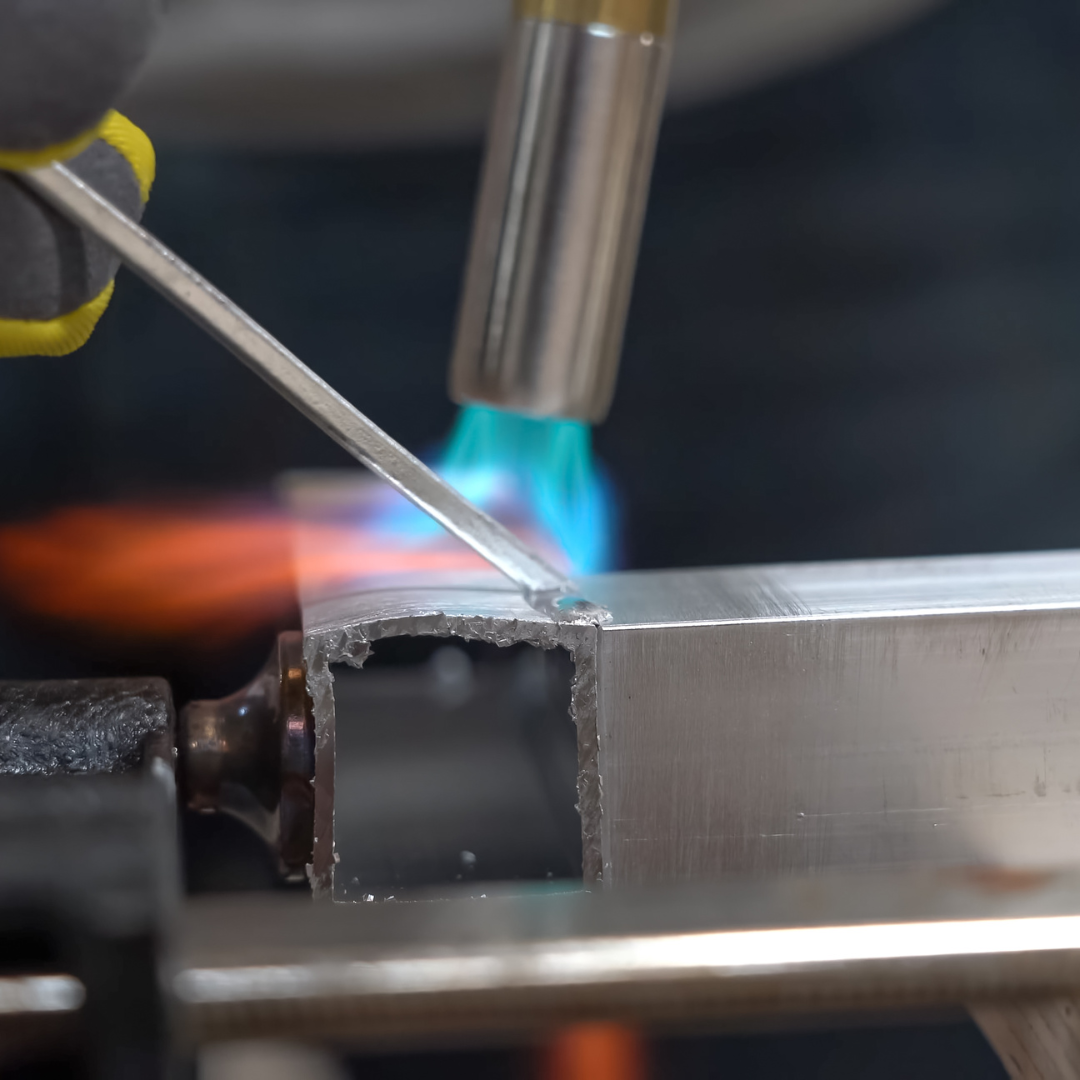

Beyond the Sparks: Unveiling the Hidden Dangers of Aluminum Welding

Aluminum welding presents several health and safety risks that welders, employers, and safety professionals should be aware of:

Aluminum Fume Inhalation: During aluminum welding, fumes containing aluminum oxide particles are released. Inhalation of these fumes can lead to respiratory problems, including conditions like aluminum fume fever, which can cause flu-like symptoms such as fever, cough, and headache.

Neurological Effects: Prolonged exposure to aluminum fumes can result in aluminum-induced encephalopathy, a condition that affects the nervous system. Symptoms may include memory loss, muscle weakness, and speech impairments.

Pulmonary Issues: Aluminum welding fumes can also lead to lung problems, including fibrosis and impaired lung function. Chronic exposure to aluminum particles can increase the risk of lung cancer.

Eye and Skin Irritation: Welding with aluminum can release intense UV radiation and visible light that may cause eye damage and skin burns. Prolonged exposure can lead to more severe conditions.

Fire and Explosion Risks: Aluminum dust and particles are highly flammable and can potentially lead to fires or explosions in the workplace if not managed properly.

Mitigating the Risks with Apzem’s Welding Fume Extractor:

To protect both welders and the workplace, it’s essential to implement effective control measures. Apzem’s welding fume extractor is a reliable solution for mitigating the dangers of aluminum welding:

Efficient Fume Capture: Apzem’s extractor uses high-quality filters and a powerful fan to capture welding fumes directly at the source. This prevents the release of harmful fumes into the working environment.

Advanced Filtration: Apzem’s welding fume extractors come equipped with multi-stage filtration systems that remove particulate matter, gases, and fumes. This ensures a cleaner and healthier working environment.