Author: admin

3D Printing and Its Hidden Hazard: How our Dust Collector Safeguards Employee Health

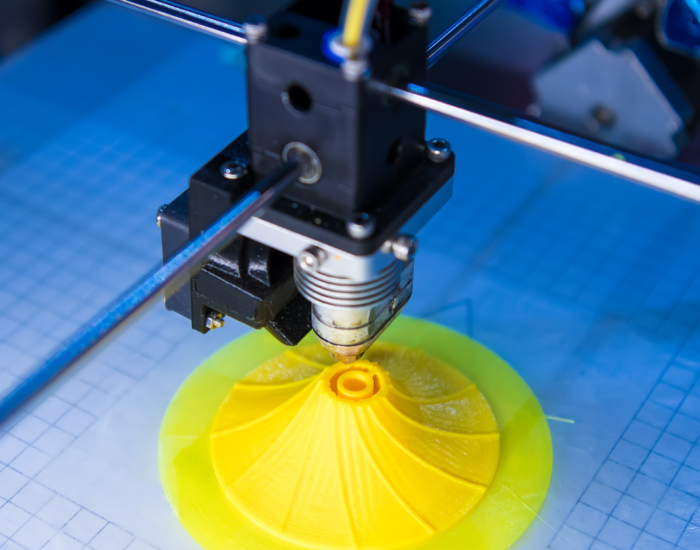

In recent years, 3D printing has revolutionized manufacturing, allowing for the rapid and cost-effective production of intricate designs and prototypes. This technology has found applications in various industries, from aerospace to healthcare. However, while 3D printing offers numerous benefits, it also presents some less obvious challenges, one of which is the generation of fine dust particles that can pose serious health risks to employees. In this blog, we’ll explore the impact of dust in 3D printing environments and discuss how Apzem’s dust collector effectively removes dust to safeguard employee health.

The Hidden Hazard of 3D Printing Dust

3D printers work by layering materials such as plastics, metals, or resins to create three-dimensional objects. During printing, these materials may release tiny particles into the air, creating a dusty environment within the workspace. This dust is often composed of materials like plastic or metal particles, which can have harmful effects on human health when inhaled or come into contact with the skin.

Health Risks Associated with 3D Printing Dust:

- Respiratory Issues: Inhaling fine dust particles generated during 3D printing can lead to respiratory problems, including coughing, wheezing, and shortness of breath. Prolonged exposure may even cause more serious conditions such as bronchitis or asthma.

- Skin Irritation: The dust produced can settle on surfaces, including the skin, leading to skin irritation and potential allergic reactions for those handling printed objects or working in the immediate vicinity.

- Eye Irritation: Dust particles can also irritate the eyes, causing redness, itching, and discomfort.

- Long-Term Health Effects: Chronic exposure to 3D printing dust may result in long-term health issues, including a higher risk of respiratory diseases and potential carcinogenic effects, particularly with certain materials.

The Solution: Apzem’s Dust Collector;

To mitigate these health risks and ensure a safe working environment for employees in 3D printing facilities, an effective dust management system is crucial. Apzem, a trusted name in industrial air quality solutions, offers a range of dust collectors designed specifically for 3D printing environments.

Here’s how Apzem’s dust collector effectively removes dust and safeguards employee health:

- High-Efficiency Filtration: Apzem’s dust collectors are equipped with high-efficiency filtration systems that capture even the smallest dust particles, ensuring that the air in the workspace remains clean and free of harmful contaminants.

- Easy Maintenance: These dust collectors are built with ease of maintenance in mind, allowing for simple filter replacement and system upkeep, reducing downtime.

- Compliance with Regulations: Apzem’s dust collectors are engineered to meet and exceed industry standards and regulations for air quality and safety, ensuring that your facility remains compliant.

How Our Dust Collectors Revolutionize the Painting and Coating Industry

The painting and coating industry plays a vital role in enhancing product aesthetics and durability. However, it faces challenges due to the generation of harmful dust particles during these processes. In this blog, we’ll explore how our dust collectors help safeguard employee health in this industry.

The Dust Challenge:

Painting and coating processes involve the application of various substances, including paints, solvents, and coatings, which can generate fine dust particles as byproducts. These dust particles, when released into the air, can have adverse effects on both the environment and the health of workers. Here are some of the key effects of dust exposure in the painting and coating industry.

- Respiratory Issues: Inhaling dust particles leads to respiratory problems and long-term conditions like asthma.

- Skin and Eye Irritation: Dust can cause skin rashes and eye irritation, affecting work efficiency.

- Long-term Risks: Exposure to toxic chemicals in dust increases the risk of serious health conditions.

- Reduced Productivity: Dust accumulation hampers productivity and requires protective gear.

To address these challenges and protect the well-being of employees, the painting and coating industry relies heavily on dust collection systems. Dust collectors are specialized devices designed to capture and remove airborne dust particles from the workplace environment. Here’s how Apzem’s dust collectors safeguard employee health.

- Efficient Dust Capture: Our dust collectors efficiently capture dust at the source, reducing inhalation risks.

- High-Quality Filtration: Our systems effectively remove fine dust particles, ensuring clean air.

- Compliance and Safety: Our systems meet industry regulations, ensuring workplace safety.

- Maintenance and Support: Comprehensive maintenance services minimize downtime and extend equipment lifespan.

Our dust collectors are essential in preventing dust-related health issues and ensuring a safer and more productive workplace in the painting and coating industry. Choose our systems to protect employee health and support your business’s success.

Mastering Sanding and Grinding: The Role of Dust Collectors in Workspace Cleanliness

Sanding and grinding are essential processes in woodworking, metalworking, and various other industries. They help shape, smooth, and refine surfaces, but they also generate a significant amount of dust and debris that can be harmful to your health and workspace. In this blog, we’ll explore the importance of dust collection in sanding and grinding operations and how our Dust Collectors, effectively remove dust and debris, making your workspace safer and more efficient.

The Dusty Dilemma:

Anyone who has ever sanded wood, metal, or any other material knows that it can create a cloud of fine dust particles that linger in the air and settle on everything in the vicinity. Not only is this dust unsightly, but it can also pose serious health risks if inhaled. Dust from sanding and grinding operations can contain harmful particles like wood dust, metal shavings, or even hazardous chemicals depending on the materials being worked on.

Health Risks:

Inhaling these dust particles can lead to various health problems, including:

- Respiratory Issues: Fine dust particles can irritate your lungs, leading to conditions like asthma, bronchitis, or even lung cancer over time.

- Allergies: Dust can trigger allergies and worsen existing respiratory conditions.

- Eye Irritation: Dust particles can also irritate your eyes, causing discomfort and potential damage.

- Fire and Explosion Hazard: In industrial settings, dust buildup can create a fire and explosion hazard if not properly managed.

Efficient Dust Collection

To combat these issues, dust collectors have become essential tools in sanding and grinding operations. Our dust collectors efficiently capture and remove dust and debris from the air, creating a cleaner and safer workspace.

Benefits of Our Dust Collectors:

- Health and Safety: Our Dust Collectors provide exceptional health and safety benefits by removing harmful dust from the air and reducing the risk of respiratory issues and other health problems.

- Cleaner Workspace: These dust collectors help maintain a clean and organized workspace, reducing the time and effort needed for cleaning up after sanding or grinding tasks.

- Efficiency: With less dust in the air, operators can work more efficiently and comfortably. Improved visibility also leads to more precise work.

Addressing a Critical Issue: Air Pollution in Asia

The air we breathe is a vital component of life, sustaining us with each inhalation. However, in many parts of the world, including Asia, the air is far from clean and pure. Air pollution has become an alarming issue, not only for the environment but also for our health. Recent studies have shown that air pollution is silently shortening the life spans of people in Asia by a staggering five years. In this blog, we will delve into the grim consequences of air pollution in Asia, explore the urgent need for action to combat this invisible killer and highlight the contributions of Apzem, an air pollution control equipment manufacturer, in this crucial battle.

The State of Air Pollution in Asia:

Asia, with its rapid industrialization and urbanization, has experienced unprecedented economic growth in recent decades. Unfortunately, this growth has come at a high cost in terms of environmental degradation, especially in terms of air quality. The region is plagued by various sources of air pollution, including vehicular emissions, industrial activities, deforestation, and the burning of fossil fuels.

Key Factors Contributing to Air Pollution in Asia:

- Industrial Emissions: Asia is home to some of the world’s largest industrial hubs, which release a significant amount of pollutants into the atmosphere. These emissions include particulate matter, sulfur dioxide (SO2), nitrogen oxides (NOx), and volatile organic compounds (VOCs).

- Transportation: The rapid increase in the number of vehicles on the road has led to higher levels of air pollution due to exhaust emissions, particularly in densely populated cities.

- Deforestation: The loss of forests in Asia not only reduces the planet’s capacity to absorb carbon dioxide but also contributes to air pollution by releasing fine particulate matter during deforestation and land-use changes.

The Health Toll:

Air pollution’s detrimental effects on health are well-documented. It is associated with a range of respiratory diseases, cardiovascular problems, and even cancer. Prolonged exposure to polluted air can lead to reduced lung function, increased risk of heart attacks, strokes, and a variety of chronic illnesses. Alarmingly, studies now indicate that the life expectancy of individuals in Asia is being shortened by an average of five years due to long-term exposure to high levels of air pollution.

Vulnerable Populations:

It’s important to note that the impact of air pollution is not evenly distributed. Vulnerable populations, such as children, the elderly, and those with pre-existing health conditions, are at a higher risk of suffering from the health consequences of air pollution. In addition, low-income communities, often living in areas with poor air quality, face greater health disparities.

Investment in Clean Technology: Encouraging the adoption of clean and sustainable technologies is crucial. Amidst this urgent need to combat air pollution, we Apzem have emerged as champions in the battle for clean air. As an air pollution control equipment manufacturer, we play a crucial role in helping industries mitigate their environmental footprint. Our innovative solutions and state-of-the-art technologies are instrumental in reducing industrial emissions, thereby contributing to cleaner air.

Indoor Air Quality in the Rubber Industry: A Neglected Issue

The rubber industry plays an indispensable role in the global economy, supplying essential materials for various sectors ranging from automotive to consumer goods. However, behind the scenes of this vibrant industry lies a potential threat to the health and well-being of workers – indoor air quality (IAQ) concerns. With the generation of rubber dust and volatile compounds, employees in the rubber industry face occupational risks that demand attention. In this blog, we delve into the significance of indoor air quality within the rubber industry and explore how Apzem, a leading manufacturer of dust collectors, has stepped up to mitigate these risks and safeguard employees.

Understanding the Indoor Air Quality Challenge:

Rubber manufacturing involves various processes such as mixing, molding, and vulcanizing, all of which contribute to the release of airborne contaminants. These contaminants primarily include rubber dust, volatile organic compounds (VOCs), and other potentially hazardous airborne particles. When these pollutants are inhaled by workers, they can lead to various health issues, including respiratory problems, skin irritation, eye discomfort, and even long-term complications like lung diseases.

Occupational Risks in the Rubber Industry:

- Respiratory Concerns: Rubber dust consists of fine particles that can easily become airborne during production. Prolonged exposure to these particles can lead to respiratory issues like asthma, bronchitis, and chronic obstructive pulmonary disease (COPD).

- Skin and Eye Irritation: VOCs emitted during rubber processing can cause skin irritation and allergies. Additionally, rubber dust particles can lead to eye irritation and discomfort.

- Carcinogenic Compounds: Certain rubber manufacturing processes release chemicals that are potentially carcinogenic. Long-term exposure to these compounds may increase the risk of cancer among workers.

The rubber industry’s journey towards safeguarding its employees from the occupational risks associated with indoor air quality has been greatly aided by Apzem’s innovative dust collection solutions. By efficiently capturing rubber dust particles and VOCs, these systems contribute to creating a healthier and safer work environment. As the industry continues to evolve, prioritizing indoor air quality will remain a crucial factor in ensuring the well-being of those who contribute to its success.