Product Details

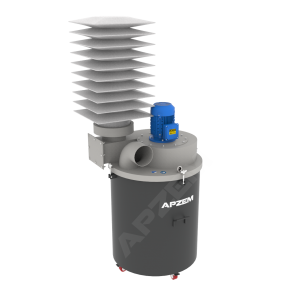

Drum type dust collector

APZEM two stages mechanical dust collectors are used where application to extract dust utilizing larger air capacity and covering multiple sources. Ideally the source of collection should not be too far from the system and should Dust avoid the mixture of dust mixing with the actual product thus reducing / avoiding contamination of product. Further more use of dust collector leads to cleaner working environment.

Product Catalogue

Description

Drum type dust collector

Drum type dust collector

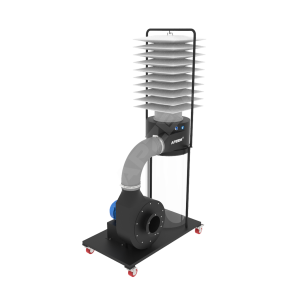

Drum type dust collectors are used where application to extract dust utilizing larger air capacity and covering multiple sources. Ideally the source of collection should not be too far from the system and should Dust avoid the mixture of dust mixing with the actual product thus reducing / avoiding contamination of product. Further more use of dust collector leads to cleaner working environment.

FEATURES

- Industrial-quality construction effectively handles collection of wood chips and sawdust

- Quick-install collection bag makes emptying and re-attaching a snap

- Single-stage design for economical and quiet operation

- Includes four casters for maneuverability and total portability

- High air velocity (CFM) design stands up to any competitive specifications

- Permanently lubricated, totally enclosed, fan-cooled motors are rated for continuous-duty

- Fully mobile with built-in casters

- Dust bags are 99% efficient.

- High filtration area.

- Easy filter replacement

- 12 gauge, powder-coated, steel casing.

OPTIONAL FEATURES

- filter choke indicator

- filter burst indicator

-

- Grinding and Buffing Machine

- Wood industries

- Sandblasting, Grit & shot blasting

- Planer machine

- Table saw machine

- Mixers, foundry

- For Portable or Stationary Applications

- Agro Industries

- Wood working industries

- Paper Mills

- Textile Industries

- Tobacco Processing Industries

- Food Processing Industries (Grain Handling)

APZEM two stages mechanical dust collectors are used where application to extract dust utilizing larger air capacity and covering multiple sources. Ideally the source of collection should not be too far from the system and should Dust avoid the mixture of dust mixing with the actual product thus reducing / avoiding contamination of product. Further more use of dust collector leads to cleaner working environment.

| BASIC DETAILS | TD750 | TD760 | TD770 |

| SUCTION CAPACITY (CMH/CFM) | 1700/1000 | 2000/1200 | 3400/2000 |

| OVERALL DIMENSIONS (L X W X H) | 810 X 875 X 1900 mm | 970 X 900X 1970 mm | 970 X 1030 X 2020 mm |

| MACHINE WEIGHT (APPROX.) | 100Kg | 130Kg | 150Kg |

| SHIPPING WEIGHT (APPROX.) | 125kg | 160Kg | 185Kg |

| MOTOR POWER | 2HP | 3HP | 5HP |

| MOTOR SPEED | 2880 RPM | 2880 RPM | 2880 RPM |

| POWER SUPPLY | 3 PHASE / 50Hz | 3 PHASE / 50Hz | 3 PHASE / 50Hz |

| RATED CURRENT | 3.2 A | 4.49 A | 7 A |

| NOISE LEVEL | <82 | <82 | <85 |

| STATIC PRESSURE | 100mm OF WG | 100mm OF WG | 100mm OF WG |

| IMPELLER SIZE | 300mm DIA | 380mm DIA | 400mm DIA |

| INLET SIZE | 150mm | 150mm | 200mm |

| FILTER DETAILS | |||

| FILTER SURFACE | 33.7 sq. ft | 33.7 sq. ft | 33.7 sq. ft |

| TYPE OF FILTER | FILTER BAG | FILTER BAG | FILTER BAG |

| FILTER MEDIA | NON-WOVEN NEEDLE FELT POLYESTER | NON-WOVEN NEEDLE FELT POLYESTER | NON-WOVEN NEEDLE FELT POLYESTER |

| FILTER EFFICIENCY | 99% EFFICIENCY @ 5MICRONS | 99% EFFICIENCY @ 5MICRONS | 99% EFFICIENCY @ 5MICRONS |