3D Printing and Its Hidden Hazard: How our Dust Collector Safeguards Employee Health

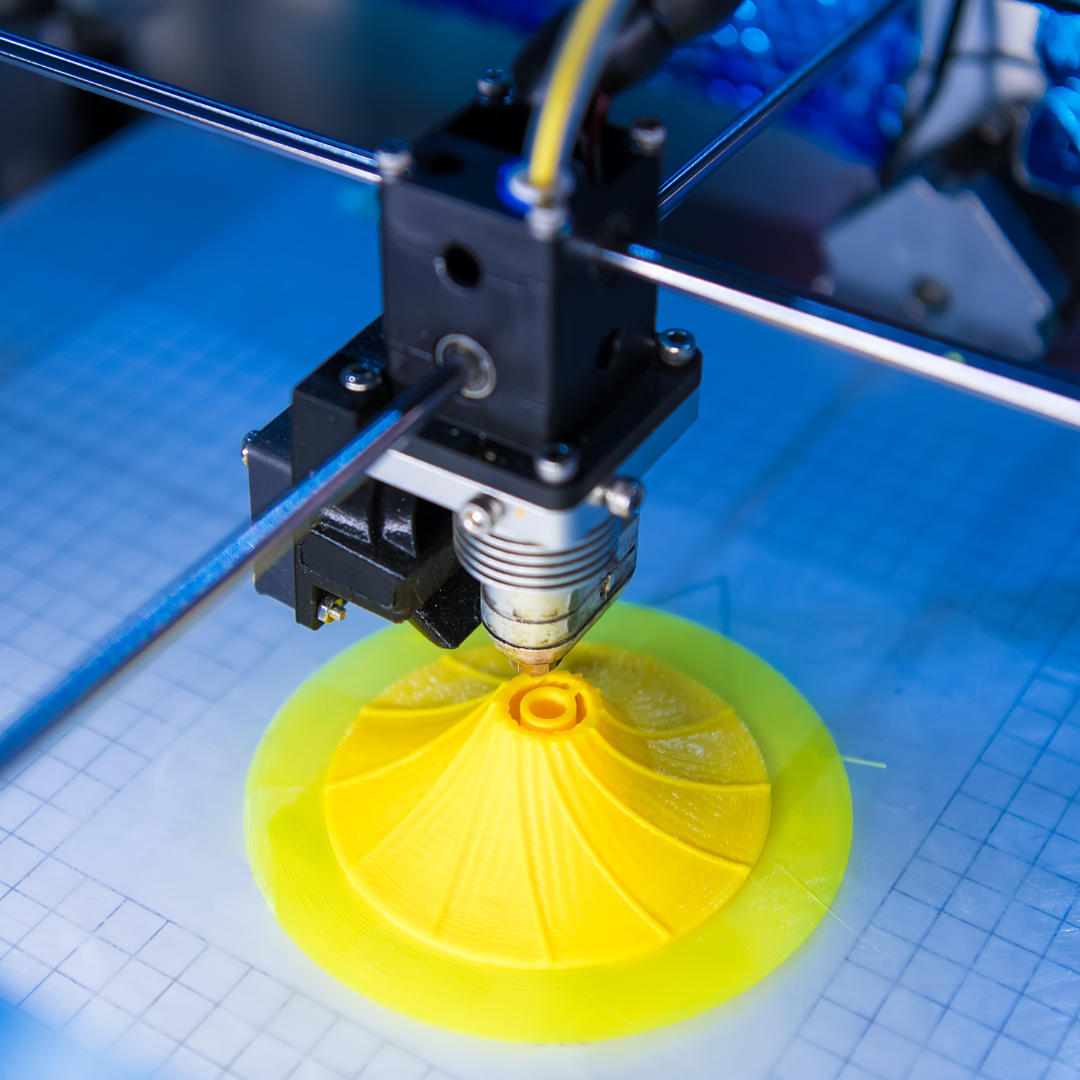

In recent years, 3D printing has revolutionized manufacturing, allowing for the rapid and cost-effective production of intricate designs and prototypes. This technology has found applications in various industries, from aerospace to healthcare. However, while 3D printing offers numerous benefits, it also presents some less obvious challenges, one of which is the generation of fine dust particles that can pose serious health risks to employees. In this blog, we’ll explore the impact of dust in 3D printing environments and discuss how Apzem’s dust collector effectively removes dust to safeguard employee health.

The Hidden Hazard of 3D Printing Dust

3D printers work by layering materials such as plastics, metals, or resins to create three-dimensional objects. During printing, these materials may release tiny particles into the air, creating a dusty environment within the workspace. This dust is often composed of materials like plastic or metal particles, which can have harmful effects on human health when inhaled or come into contact with the skin.

Health Risks Associated with 3D Printing Dust:

- Respiratory Issues: Inhaling fine dust particles generated during 3D printing can lead to respiratory problems, including coughing, wheezing, and shortness of breath. Prolonged exposure may even cause more serious conditions such as bronchitis or asthma.

- Skin Irritation: The dust produced can settle on surfaces, including the skin, leading to skin irritation and potential allergic reactions for those handling printed objects or working in the immediate vicinity.

- Eye Irritation: Dust particles can also irritate the eyes, causing redness, itching, and discomfort.

- Long-Term Health Effects: Chronic exposure to 3D printing dust may result in long-term health issues, including a higher risk of respiratory diseases and potential carcinogenic effects, particularly with certain materials.

The Solution: Apzem’s Dust Collector;

To mitigate these health risks and ensure a safe working environment for employees in 3D printing facilities, an effective dust management system is crucial. Apzem, a trusted name in industrial air quality solutions, offers a range of dust collectors designed specifically for 3D printing environments.

Here’s how Apzem’s dust collector effectively removes dust and safeguards employee health:

- High-Efficiency Filtration: Apzem’s dust collectors are equipped with high-efficiency filtration systems that capture even the smallest dust particles, ensuring that the air in the workspace remains clean and free of harmful contaminants.

- Easy Maintenance: These dust collectors are built with ease of maintenance in mind, allowing for simple filter replacement and system upkeep, reducing downtime.

- Compliance with Regulations: Apzem’s dust collectors are engineered to meet and exceed industry standards and regulations for air quality and safety, ensuring that your facility remains compliant.