Month: November 2023

Resolving Unpleasant Odors through Dust Collection and Odor Control

In the dynamic landscape of industrial processes, managing air quality is a paramount concern. As industries strive for efficiency and sustainability, addressing issues like dust and odors becomes crucial not only for compliance but also for creating a healthier work environment. This blog explores the concept of integrated dust collection and odor control, shedding light on the types of odors prevalent in industries and how manufacturers of dust collectors and scrubbers are pioneering solutions to combat these challenges.

Understanding Industrial Odors:

Industrial processes generate a myriad of odors, each posing unique challenges to environmental and occupational health. Some common types of odors in industries include:

- Chemical Odors: As a result of the use of various chemicals in manufacturing processes, these odors can be harsh and potentially harmful.

- Biological Odors: Arising from organic materials, such as those in food processing or wastewater treatment, biological odors can be unpleasant and pose health risks.

- Combustion Odors: Associated with processes involving burning or combustion, these odors can range from smoky to acrid.

- Volatile Organic Compounds (VOCs): Commonly emitted during industrial activities, VOCs contribute to air pollution and can have adverse health effects.

- Particulate Matter Odors: Arising from the release of fine particles during manufacturing, these odors can be irritating and harmful if inhaled.

The Role of Dust Collectors and Scrubbers:

Dust collectors and scrubbers play a pivotal role in addressing both dust and odor challenges in industrial settings. Here’s how:

Dust Collection & Odor Control

- Efficient Filtration: Advanced dust collectors employ high-efficiency filtration systems to capture and remove particulate matter from the air, preventing it from dispersing into the environment.

- Scrubbers: These systems utilize chemical reactions to neutralize and eliminate odorous compounds from the air. By choosing the appropriate scrubbing media, manufacturers can target specific odors emitted in various industrial processes.

Benefits to Industries:

- Compliance: By investing in integrated dust collection and odor control systems, industries can ensure compliance with stringent environmental regulations, avoiding potential fines and penalties.

- Employee Health and Safety: Creating a cleaner and odor-free work environment contributes to the well-being of employees, reducing the risk of respiratory issues and other health concerns associated with exposure to pollutants.

Operational Efficiency: Efficient air quality control systems contribute to the overall efficiency of industrial processes by minimizing downtime, maintenance costs, and disruptions caused by environmental concerns.

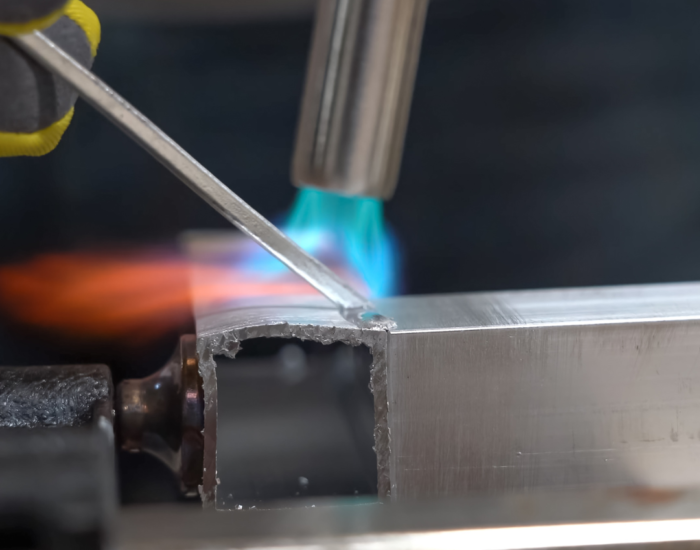

Beyond the Sparks: Unveiling the Hidden Dangers of Aluminum Welding

Aluminum welding presents several health and safety risks that welders, employers, and safety professionals should be aware of:

Aluminum Fume Inhalation: During aluminum welding, fumes containing aluminum oxide particles are released. Inhalation of these fumes can lead to respiratory problems, including conditions like aluminum fume fever, which can cause flu-like symptoms such as fever, cough, and headache.

Neurological Effects: Prolonged exposure to aluminum fumes can result in aluminum-induced encephalopathy, a condition that affects the nervous system. Symptoms may include memory loss, muscle weakness, and speech impairments.

Pulmonary Issues: Aluminum welding fumes can also lead to lung problems, including fibrosis and impaired lung function. Chronic exposure to aluminum particles can increase the risk of lung cancer.

Eye and Skin Irritation: Welding with aluminum can release intense UV radiation and visible light that may cause eye damage and skin burns. Prolonged exposure can lead to more severe conditions.

Fire and Explosion Risks: Aluminum dust and particles are highly flammable and can potentially lead to fires or explosions in the workplace if not managed properly.

Mitigating the Risks with Apzem’s Welding Fume Extractor:

To protect both welders and the workplace, it’s essential to implement effective control measures. Apzem’s welding fume extractor is a reliable solution for mitigating the dangers of aluminum welding:

Efficient Fume Capture: Apzem’s extractor uses high-quality filters and a powerful fan to capture welding fumes directly at the source. This prevents the release of harmful fumes into the working environment.

Advanced Filtration: Apzem’s welding fume extractors come equipped with multi-stage filtration systems that remove particulate matter, gases, and fumes. This ensures a cleaner and healthier working environment.

Clearing the Air: Industrial Dust Collection Benefits

In the world of manufacturing, maintaining a clean and safe work environment is crucial. Industrial facilities, whether they produce metal, wood, food, chemicals, or other products, often generate significant amounts of dust and particulate matter. These airborne contaminants not only pose health risks to workers but also threaten the efficiency and longevity of machinery. That’s where industrial dust collection systems come into play. In this blog, we’ll explore how these systems can help reduce costs and improve overall efficiency in manufacturing facilities.

The Dust Problem

Before delving into the benefits of industrial dust collection systems, it’s essential to understand the scope of the problem they address. Dust and particulate matter can originate from various sources, including cutting, grinding, sanding, and even material handling processes. This dust poses multiple challenges, such as:

- Health and safety risks: Inhaling airborne particles can lead to respiratory problems and other health issues for employees. To protect their well-being, companies must comply with stringent workplace safety regulations.

- Machinery damage: Dust particles can infiltrate and damage sensitive machinery components, leading to costly repairs and downtime.

- Reduced product quality: Dust settling on products can compromise their quality and aesthetics, potentially leading to increased rejection rates and customer dissatisfaction.

- Environmental concerns: Many manufacturing facilities are subject to environmental regulations and must control dust emissions to minimize their impact on the surrounding community.

Industrial Dust Collection Systems: A Solution

Industrial dust collection systems offer a comprehensive solution to these problems. These systems use various methods, including filtration and cyclonic separation, to capture and remove airborne dust and particulate matter from the air. Here’s how they can help reduce costs and improve efficiency in manufacturing facilities:

- Improved worker health and safety: By removing harmful particles from the air, dust collection systems create a safer working environment. Fewer health issues mean lower healthcare costs, reduced absenteeism, and a more motivated workforce.

- Increased machinery efficiency and lifespan: Dust collection prevents particles from entering and damaging machinery, leading to fewer breakdowns and longer machine life. This results in lower maintenance and replacement costs, as well as increased production uptime.

- Enhanced product quality: With a clean and dust-free workspace, the risk of product contamination is significantly reduced. This means less rework, fewer rejected products, and improved customer satisfaction.