Month: April 2019

Master Batches

MASETR BATCHES - DUST COLLECTION SYSTEMS AND WASTE MANAGEMENT FOR MASTER BATCHES

Wood Working involves many kinds of processes such as cutting, sanding, drilling, banding etc. These processes generates large amount of wood dusts. Very fine particles of wood dust will be generated and efficient handling of these dust particles is highly important for ensuring the safety of the employees. By extraction of wood working dust, workplace environment will be improved and eventually productivity will also be increased. More over the extracted wood dust particles .

Woodworking, involving everything from small hand tools to large CNCs, whether cutting, sanding, planning, edge banding, dowel drilling, and so on, can create large amounts of wood dust. To handle these various applications safely and efficiently, APZEM has developed a wide range of products and systems including dust collectors, piping / ducting, fans, conveyors, silos and automated control systems. These systems make it possible for customers to not only achieve a good working environment, but also recycle wood waste, which can represent a large economic value. Another hazard associated with wood working is combustible dust. Wood waste can profitably be recycled into new material (i.e. MDF-board) or into energy if used as bio-fuel. Well designed and efficient wood waste handling installations have become a major part of the woodworking industry.

SCOURER DUST REMOVAL SOLUTION - MOBILE DUST COLLECTOR FOR POWDER DUST

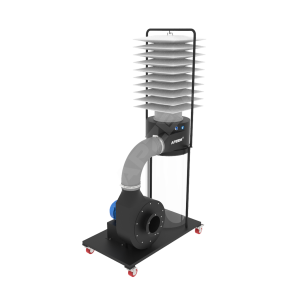

Portable Dust Collector

Apzem’s Portable Dust Collector suitable for capturing dust at the source. Portable dust collectors are self contained system with fully automatic pulse air cleaning arrangement and industrial grade castor wheel affixed at bottom for maximum portability. As an optional upgrade some of our portable dustcollectors are accompanied with flexible arm with hood and control arrangement Portable dustcollectors will be an economical option when sources generating dusts is not fixed at one location

AUTOMATIC PULSE AIR CLEANING ARRANGEMENT

- Fully mobile with built-in casters

- Cartridge filters are 99% efficient.

- 12 gauge, powder-coated, steel casing

- Easy handling of dust tray.

- Filter choking alarm

- Self cleaning reverse pulse system

- 3 meter Flexible arm with capturing Hood

SIFTING DUST REMOVAL SOLUTION - BAGFILTER DUST COLLECTOR

Sifting Dust Removal

Bagfilter or Baghouse dust collector are a giant centralized industrial dust control equipment used for collection and filtration of harmful, nuisance dusts in various industries like Food Industry , cement plants, Fertilizer Industries, Woodworking & Glass manufacturing industries and other Manufacturing Industries.

- Flow:upto30,000 CFM

- Filtration :upto5 microns

- MOC:Mild Steel / SS 304 /SS316

- Finish: Powder coated / Matt finish

- Power option :3 Phase

HIGHLY ADVANCED FEATURES

Related Products :

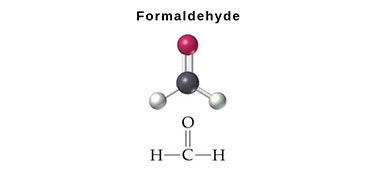

Formaldehyde

FORMALDEHYDE

Formaldehyde is a naturally occurring chemical compound. It is a colourless water-soluble, flammable gas with pungent odour in its natural state, but it can adopt many forms. Formalin that is used in pathology laboratories is a solution containing 40% formaldehyde. Formalin solution when exposed to open air evaporates as formaldehyde gas at normal room temperature. Exposure to higher levels of formaldehyde concentration has immediate health effects ,it is also classified as carcinogenic. Long term exposure leads to severe health effects. Formaldehyde is a naturally occurring chemical compound, all organisms including human beings produce a small quantity of formaldehyde as a result of metabolic process. Formaldehyde gas is converted to other forms for its usage in various chemical process.

It’s used in paint industry, viny flooring, pressed wood products such as particle board, plywood, fibreboard, glues and adhesives, fertilizers, pesticides, used as industrial fungicide, germicide, and disinfectant, formalin solution is used in medical laboratories and hospitals. Initial symptoms of formaldehyde exposure are irritation of eyes, throat and nose, coughing, headache, wheezing etc. Long term exposure may lead to cancer. Some people are more sensitive to formaldehyde, while some are less sensitive to the same level of formaldehyde concentration. Inhalation of formaldehyde gas causes bronchitis and pneumonia. As per OSHA(Occupational Safety and Health Administration) standards the safe level of exposure is an average of 0.75 PPM over a period of 8-hours. The maximum level of formaldehyde concentration a person can be exposed to is 2.0 PPM for a period not more than 15 inutes.

DUST REMOVAL SOLUTION - MOBILE DUST COLLECTOR FOR POWDER DUST

Portable Dust Collector

Apzem’s Portable Dust Collector suitable for capturing dust at the source. Portable dust collectors are self contained system with fully automatic pulse air cleaning arrangement and industrial grade castor wheel affixed at bottom for maximum portability. As an optional upgrade some of our portable dustcollectors are accompanied with flexible arm with hood and control arrangement Portable dustcollectors will be an economical option when sources generating dusts is not fixed at one location

AUTOMATIC PULSE AIR CLEANING ARRANGEMENT

- Fully mobile with built-in casters

- Cartridge filters are 99% efficient.

- 12 gauge, powder-coated, steel casing

- Easy handling of dust tray.

- Filter choking alarm

- Self cleaning reverse pulse system

- 3 meter Flexible arm with capturing Hood

SIFTING DUST REMOVAL SOLUTION - BAGFILTER DUST COLLECTOR

Sifting Dust Removal

Bagfilter or Baghouse dust collector are a giant centralized industrial dust control equipment used for collection and filtration of harmful, nuisance dusts in various industries like Food Industry , cement plants, Fertilizer Industries, Woodworking & Glass manufacturing industries and other Manufacturing Industries.

- Flow:upto30,000 CFM

- Filtration :upto5 microns

- MOC:Mild Steel / SS 304 /SS316

- Finish: Powder coated / Matt finish

- Power option :3 Phase

HIGHLY ADVANCED FEATURES

Related Products :

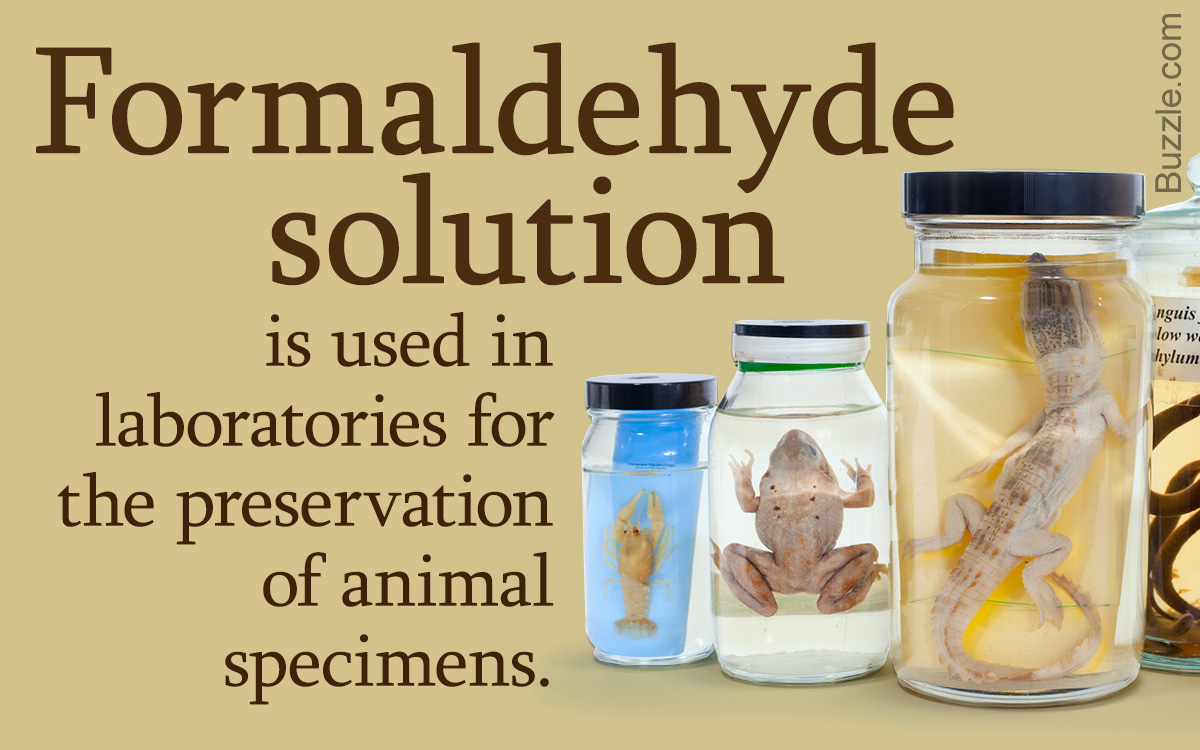

Laboratories

LABORATORIES - DUST COLLECTION SYSTEMS AND WASTE MANAGEMENT FOR WOOD DUST

Wood Working involves many kinds of processes such as cutting, sanding, drilling, banding etc. These processes generates large amount of wood dusts. Very fine particles of wood dust will be generated and efficient handling of these dust particles is highly important for ensuring the safety of the employees. By extraction of wood working dust, workplace environment will be improved and eventually productivity will also be increased. More over the extracted wood dust particles .

Woodworking, involving everything from small hand tools to large CNCs, whether cutting, sanding, planning, edge banding, dowel drilling, and so on, can create large amounts of wood dust. To handle these various applications safely and efficiently, APZEM has developed a wide range of products and systems including dust collectors, piping / ducting, fans, conveyors, silos and automated control systems. These systems make it possible for customers to not only achieve a good working environment, but also recycle wood waste, which can represent a large economic value. Another hazard associated with wood working is combustible dust. Wood waste can profitably be recycled into new material (i.e. MDF-board) or into energy if used as bio-fuel. Well designed and efficient wood waste handling installations have become a major part of the woodworking industry.

SCOURER DUST REMOVAL SOLUTION - MOBILE DUST COLLECTOR FOR POWDER DUST

Portable Dust Collector

Apzem’s Portable Dust Collector suitable for capturing dust at the source. Portable dust collectors are self contained system with fully automatic pulse air cleaning arrangement and industrial grade castor wheel affixed at bottom for maximum portability. As an optional upgrade some of our portable dustcollectors are accompanied with flexible arm with hood and control arrangement Portable dustcollectors will be an economical option when sources generating dusts is not fixed at one location

AUTOMATIC PULSE AIR CLEANING ARRANGEMENT

- Fully mobile with built-in casters

- Cartridge filters are 99% efficient.

- 12 gauge, powder-coated, steel casing

- Easy handling of dust tray.

- Filter choking alarm

- Self cleaning reverse pulse system

- 3 meter Flexible arm with capturing Hood

SIFTING DUST REMOVAL SOLUTION - BAGFILTER DUST COLLECTOR

Sifting Dust Removal

Bagfilter or Baghouse dust collector are a giant centralized industrial dust control equipment used for collection and filtration of harmful, nuisance dusts in various industries like Food Industry , cement plants, Fertilizer Industries, Woodworking & Glass manufacturing industries and other Manufacturing Industries.

- Flow:upto30,000 CFM

- Filtration :upto5 microns

- MOC:Mild Steel / SS 304 /SS316

- Finish: Powder coated / Matt finish

- Power option :3 Phase

HIGHLY ADVANCED FEATURES

Related Products :

Hexavalent Chromium

HEXAVALENT CHROMIUM – SOLUTION FOR BEING SAFE FROM CHROMIUM

Hexavalent chromium is one of the valence states of the element chromium. It is usually produced by an industrial process. Pigments in Plastics, Dyes, Paints inks Chromium metal is added to alloy steel to increase hardenability and corrosion resistance. A major source of worker exposure to Cr(VI) occurs during “hot work” such as welding on stainless steel and other alloy steels containing chromium metal. Some major industrial sources of hexavalent chromium are

- chromate pigments in dyes, paints, inks, and plastics

- chromates added as anti-corrosive agents to paints, primers and other surface coatings

- chrome plating by depositing chromium metal onto an item’s surface using a solution of chromic acid

- particles released during smelting of ferrochromium ore

- fume from welding stainless steel or nonferrous chromium alloys

- impurity present in portland cement.

Employees can inhale airborne hexavalent chromium as a dust, fume or mist while:

- producing chromate pigments and powders; chromic acid; chromium catalysts, dyes, and coatings • working near chrome electroplating

- welding and hot working stainless steel, high chrome alloys and chrome-coated metal

- applying and removing chromate-containing paints and other surface coatings.How hexavalent chromium affects the nose, throat and lungs breathing in high levels of hexavalent chromium can cause irritation to the nose and throat.

DUST REMOVAL SOLUTION - MOBILE DUST COLLECTOR FOR POWDER DUST

Portable Dust Collector

Apzem’s Portable Dust Collector suitable for capturing dust at the source. Portable dust collectors are self contained system with fully automatic pulse air cleaning arrangement and industrial grade castor wheel affixed at bottom for maximum portability. As an optional upgrade some of our portable dustcollectors are accompanied with flexible arm with hood and control arrangement Portable dustcollectors will be an economical option when sources generating dusts is not fixed at one location

AUTOMATIC PULSE AIR CLEANING ARRANGEMENT

- Fully mobile with built-in casters

- Cartridge filters are 99% efficient.

- 12 gauge, powder-coated, steel casing

- Easy handling of dust tray.

- Filter choking alarm

- Self cleaning reverse pulse system

- 3 meter Flexible arm with capturing Hood

SIFTING DUST REMOVAL SOLUTION - BAGFILTER DUST COLLECTOR

Sifting Dust Removal

Bagfilter or Baghouse dust collector are a giant centralized industrial dust control equipment used for collection and filtration of harmful, nuisance dusts in various industries like Food Industry , cement plants, Fertilizer Industries, Woodworking & Glass manufacturing industries and other Manufacturing Industries.

- Flow:upto30,000 CFM

- Filtration :upto5 microns

- MOC:Mild Steel / SS 304 /SS316

- Finish: Powder coated / Matt finish

- Power option :3 Phase

HIGHLY ADVANCED FEATURES

Related Products :

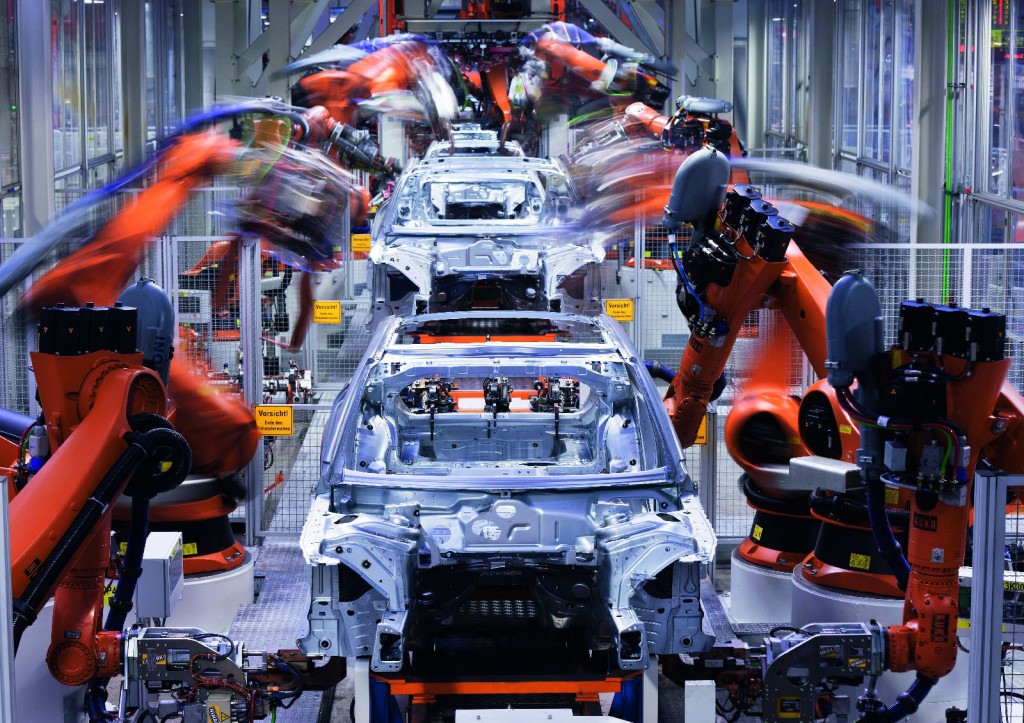

Automotive

AUTOMOTIVE INDUSTRY – Odor, Fume & Dust Control Solution

The manufacture of electrodes, cells and modules/packs for large-format power batteries is still in its infancy. One thing, however, is already perfectly clear: the battery manufacturing operation needs to become faster and less expensive if lithium-ion energy storage technology is to establish itself successfully in the target markets. The sensitive chemistry of the cells means that these cost and time savings absolutely cannot come at the expense of quality, which needs to remain very high. The solution, therefore, lies in fully automating and integrating production lines.

The automation portfolio needs to provide comprehensive support for the development process, from the pilot system to in-line integration. Totally Integrated Automation from Siemens makes it possible to optimize all processes throughout the production line and across the entire lifecycle of the plant. Uniform data management, engineering and communication standards ensure that all production steps, from electrode manufacturing to cell assembly to pack mounting and final quality tests, are optimally coordinated.

DUST REMOVAL SOLUTION - MOBILE DUST COLLECTOR FOR POWDER DUST

Portable Dust Collector

Apzem’s Portable Dust Collector suitable for capturing dust at the source. Portable dust collectors are self contained system with fully automatic pulse air cleaning arrangement and industrial grade castor wheel affixed at bottom for maximum portability. As an optional upgrade some of our portable dustcollectors are accompanied with flexible arm with hood and control arrangement Portable dustcollectors will be an economical option when sources generating dusts is not fixed at one location

AUTOMATIC PULSE AIR CLEANING ARRANGEMENT

- Fully mobile with built-in casters

- Cartridge filters are 99% efficient.

- 12 gauge, powder-coated, steel casing

- Easy handling of dust tray.

- Filter choking alarm

- Self cleaning reverse pulse system

- 3 meter Flexible arm with capturing Hood

SIFTING DUST REMOVAL SOLUTION - BAGFILTER DUST COLLECTOR

Sifting Dust Removal

Bagfilter or Baghouse dust collector are a giant centralized industrial dust control equipment used for collection and filtration of harmful, nuisance dusts in various industries like Food Industry , cement plants, Fertilizer Industries, Woodworking & Glass manufacturing industries and other Manufacturing Industries.

- Flow:upto30,000 CFM

- Filtration :upto5 microns

- MOC:Mild Steel / SS 304 /SS316

- Finish: Powder coated / Matt finish

- Power option :3 Phase